IES Utilities Group is delivering a step-change innovation to the UK water sector through introducing Comprex® Impulse Cleaning. It’s patented, computer-operated, trenchless cleaning solution is new to the UK, yet proven across Europe. It offers class-leading cleaning performance, minimal environmental impact, unparalleled safety, and outstanding commercial value.

This low-disruption, high-performance system removes sediment, biofilms, and mineral deposits from pressurised water pipes without the need for chemicals, excavation, or high-water use. The process uses carefully modulated medical grade air and water pulses to deliver results that far exceed traditional methods in both quality and longevity.

Many UK water companies are undertaking extensive mains renewal programmes during AMP8, driven by the need to tackle leakage, frequent bursts, or persistent water quality issues. These programmes often come with significant cost and disruption.

At the same time, water networks face growing pressure to improve water quality, reduce operational carbon, protect ageing infrastructure, and enhance the customer experience.

Where pipes are still structurally sound, some companies are exploring an alternative approach: using Comprex Impulse cleaning to target sections with water quality concerns. This method can extend the life of existing pipes, reduce disruption, and deliver significant savings compared to a full replacement.

This shift in thinking creates opportunities to clean large areas of the drinking water distribution network, while staying within the original mains replacement budgets.

Traditional cleaning methods, like flushing, ice pigging, or mechanical scraping, can be:

What the industry needs is a safer, smarter, low carbon alternative – like Comprex.

Comprex® is a patented, computer-controlled cleaning system that uses short, pulsed bursts of medical grade air and water to create high shear velocities (up to 20 m/s) inside pipes. This energy detaches biofilms, sediments, and hardened deposits, restoring internal conditions and flow to near-new standards.

Why Comprex® is class-leading:

This service-delivery model ensures all works are carried out by trained IES technicians only (no subcontractors) with strict adherence to client-approved RAMS, full operating procedures, and built-in system fail-safes. Safety is engineered into every stage of the process.

Unlike many alternative systems, Comprex® requires no complicated pre-conditions or extensive setup. It uses standard hydrant or valve access and can be completed within regular operational windows, often without customers even noticing.

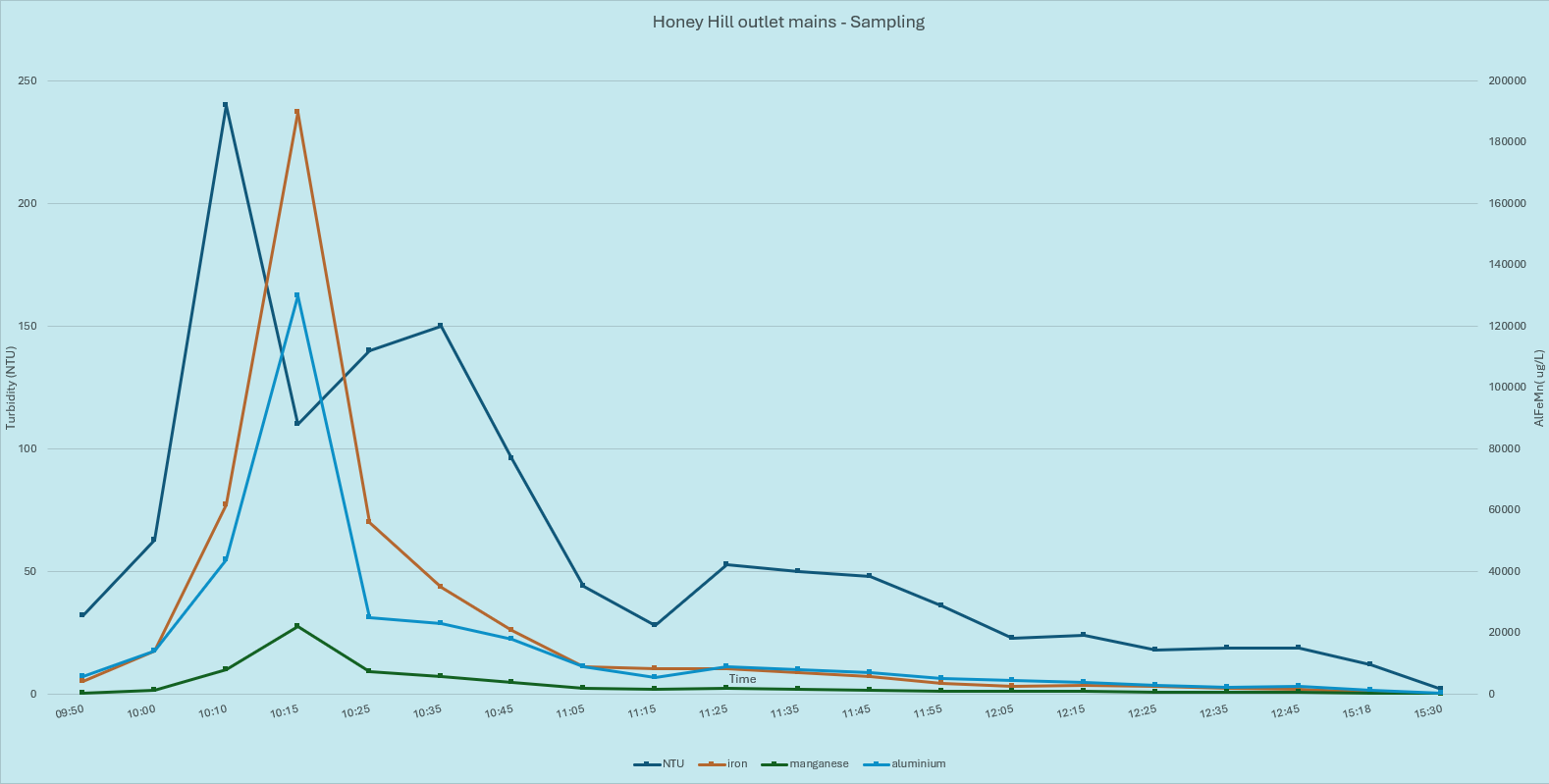

Results from the Northumbrian UK pilot showed:

The system is controlled via digital interface, making calibration, monitoring, and reporting simple and transparent. Pressure levels are automatically kept within safe operating parameters to prevent risk to the asset or operators.

To talk to our project management team call 0161 791 1496

or email info@iesutilities.co.uk